Investing in a concrete batching plant is one of the most significant strategic decisions a construction or ready-mix company can make. A common mistake is to assume that bigger is always better. In reality, the key to profitability is not size, but right-sizing. Choosing a plant with a capacity that is perfectly matched to your business model and market demand is crucial for optimizing your return on investment. This guide provides a clear comparison between small batch plants and large, high-capacity systems, and presents several business model scenarios to help you determine which configuration is the right fit for your company.

Small Batch Plants: Agility and Precision

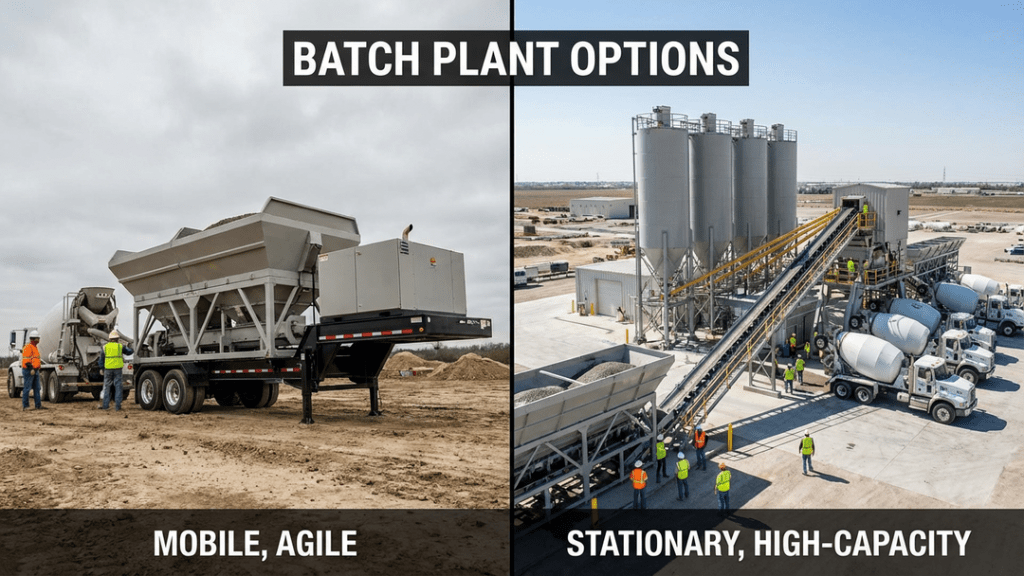

Small batch plants, such as the mobile and compact models offered by MEKA, is designed for agility, flexibility, and project-specific needs. These plants typically have a production capacity of 30-60 cubic meters per hour.

Advantages:

Lower Initial Investment: The upfront cost is significantly lower, making it more accessible for smaller companies or as a first plant.

Smaller Footprint: They require much less land, making them ideal for installation on tight urban construction sites.

Lower Operational Costs: They consume less energy and require fewer staff to operate.

Mobility: Many compact plants are designed to be mobile, allowing them to be easily moved from one project site to the next.

Limitations:

Limited Production Capacity: They cannot support a large number of projects simultaneously or handle the demands of a massive infrastructure pour.

The Large Batch Plant: Power and Scale

A large, stationary batch plant is an industrial powerhouse, designed for high-volume, continuous production. These plants can produce 100, 120, or even more cubic meters of concrete per hour.

Advantages:

High Production Volume: They can service multiple large-scale projects at once and meet the demands of a busy metropolitan market.

Economies of Scale: The cost per cubic meter of concrete produced is generally lower at high volumes due to efficiencies in material purchasing and labor.

Dedicated Infrastructure: They are typically installed with large aggregate storage bins and multiple cement silos, allowing for long, uninterrupted production runs.

Limitations:

High Initial Investment: The upfront cost for the plant and the required land and infrastructure is substantial.

Fixed Location: They are permanent installations, meaning you are tied to serving the market within a specific geographic radius.

Decision Guide: Small vs. Large

Small Batch Plants:

- Production Capacity: – 30-60 m³/hour

- Best For: On-site production, single large projects, smaller markets

- Initial Cost: Low to Medium

- Footprint: Small, can be mobile

- Staffing Needs: 2-3 people

- Scalability: Limited

Large/Stationary Plant:

- Production Capacity: 100+ m³/hour

- Best For: High-volume ready-mix, multiple large projects, major urban markets

- Initial Cost: High to Very High

- Footprint: Large, permanent

- Staffing Needs: 4-6+ people

- Scalability: High (can add mixers, silos)

Business Model Scenarios & Recommendations

Scenario 1: The Project-Focused Contractor

Business Model: A construction company that has just won a tender for a large building project (e.g., a shopping center or a high-rise residential building) that will last for 18-24 months. They need a dedicated, on-site concrete supply to control quality and timing.

Recommendation: A small, mobile batch plant*. This allows them to set up on-site, produce exactly what they need, and then move the plant to their next project once the current one is complete. It eliminates the cost and logistical uncertainty of relying on an external ready-mix supplier.

Scenario 2: The Regional Ready-Mix Supplier

Business Model: A company that aims to be the primary ready-mix supplier for a growing town or a specific region of a larger city. They will be serving a diverse customer base, from small builders to mid-sized commercial projects.

Recommendation: A *medium-sized stationary plant (e.g., 60-100 m³/hour). This provides enough capacity to handle the daily peak demand from multiple customers without the massive overhead of a very large plant. It offers a balance of production power and operational cost.

Scenario 3: The Major Infrastructure Player

Business Model: A large, established company that competes for and wins major government infrastructure projects like highways, dams, airports, or port expansions. These projects require a massive and continuous supply of concrete over a long period.

Recommendation: A large, high-capacity stationary plant or, in some cases, multiple large mobile plants. For a project like a dam, a very large stationary plant would be built on-site. For a highway project, several large mobile plants might be set up at strategic points along the route. The key is massive, reliable, and uninterrupted production.

Conclusion

Choosing the right size batch plant is a critical strategic decision that directly impacts your profitability. An oversized plant will burden you with unnecessary costs, while an undersized plant will limit your growth. By carefully analyzing your business model, your target market, and your long-term goals, you can select a plant that is perfectly sized for your needs.

As the exclusive partner for MEKA in South Africa, Nsimbi Engineering Solutions offers a complete spectrum of batching plants, from agile, compact models to the largest stationary systems. Their team of experts can help you analyze your needs and recommend the ideal plant configuration to drive your business forward.