Ready Mix Concrete

Ready mix concrete has revolutionized the construction industry across South Africa, transforming how builders, contractors, and developers approach their projects. From the bustling construction sites of Johannesburg to the coastal developments in Cape Town and Durban, ready mix concrete has become the backbone of modern construction, offering unparalleled convenience, consistency, and quality.

What is Ready Mix Concrete?

Ready mix concrete, also known as RMC, is concrete that is manufactured in a batching plant according to a set recipe and then delivered to a worksite by truck-mounted transit mixers. Unlike traditional on-site mixing, RMC arrives at your construction site in a plastic state, ready for immediate placement and compaction.

The process begins at specialized concrete batching plants where precise quantities of cement, water, aggregates (sand and stone), and admixtures are combined under controlled conditions. This factory-controlled environment ensures consistent quality and eliminates the variables that can affect concrete strength and durability when mixed on-site.

The Ready Mix Concrete Process

Batching and Mixing

The journey of ready mix concrete begins at the batching plant, where computerized systems ensure accurate proportioning of materials. Modern batching plants use sophisticated weighing systems to measure each component to within fractions of a percentage, guaranteeing consistency from batch to batch.

There are two primary methods of ready mix concrete production:

Central Mix Plants produce concrete that is completely mixed at the plant and delivered in an agitator truck that keeps the concrete in motion to prevent segregation and maintain workability.

Transit Mix Plants combine the dry materials at the plant, then add water and complete the mixing process during transport in the truck’s rotating drum.

Transportation and Delivery

Concrete mixer trucks are the vital link between the batching plant and your construction site. These specialized vehicles feature rotating drums that keep the concrete in constant motion, preventing segregation and maintaining the mixture’s homogeneous properties during transport.

The timing of delivery is crucial in ready mix concrete operations. Concrete begins to set within 30 to 60 minutes after water is added to the mixture, depending on weather conditions and admixtures used. This narrow window requires precise coordination between the batching plant, transport vehicles, and construction crews.

Advantages of Ready Mix Concrete

Quality Control and Consistency

One of the most significant advantages of ready mix concrete is the superior quality control achieved through factory production. Batching plants employ qualified technicians who monitor every aspect of production, from material quality to mixing times. Regular testing ensures that each batch meets specified strength requirements and performance criteria.

The controlled environment of a batching plant eliminates many variables that can compromise concrete quality, such as inaccurate material proportions, inadequate mixing, or contamination from job site conditions.

Cost Effectiveness

While the initial cost per cubic meter of ready mix concrete may appear higher than site-mixed alternatives, the total project cost is often lower when all factors are considered. RMC eliminates the need for on-site storage of materials, reduces labor requirements, and minimizes equipment needs at the construction site.

The reduced waste associated with ready mix concrete also contributes to cost savings. Precise ordering means you receive exactly what you need, eliminating the excess materials and disposal costs common with site mixing.

Time Savings and Efficiency

Ready mix concrete dramatically reduces construction timelines. There’s no need to source, store, and manage individual concrete ingredients on-site. Construction crews can focus on placement and finishing rather than mixing, leading to improved productivity and faster project completion.

The reliability of scheduled deliveries allows for better project planning and resource allocation, reducing downtime and improving overall construction efficiency.

Labor Reduction

By eliminating the need for on-site mixing, ready mix concrete significantly reduces labor requirements. This is particularly valuable in South Africa’s construction market, where skilled labor can be challenging to find and expensive to maintain.

Space Optimization

Construction sites, especially in urban areas, often have limited space for material storage and mixing operations. Ready mix concrete eliminates the need for cement storage silos, aggregate stockpiles, and mixing equipment, freeing up valuable site space for other construction activities.

Types and Applications

Ready mix concrete can be customized to meet virtually any construction requirement. Common grades used in South African construction include:

15 MPa Concrete is suitable for foundations, footings, and non-structural applications where moderate strength is required.

20 MPa Concrete serves well for residential foundations, driveways, and light commercial applications.

25 MPa Concrete is ideal for structural elements in residential construction, including slabs, beams, and columns.

30 MPa and Higher grades are used for commercial and industrial structures requiring high strength and durability.

Specialized mixes can be designed for specific applications, such as high-early-strength concrete for fast-track construction, waterproof concrete for basements and water-retaining structures, or lightweight concrete for reducing structural loads.

Quality Standards and Testing

In South Africa, ready mix concrete must comply with SANS 2001-CC1 standards, which specify requirements for constituent materials, concrete composition, production, and testing. Regular testing includes slump tests for workability, compression tests for strength verification, and durability assessments for long-term performance.

Reputable ready mix suppliers maintain comprehensive quality assurance programs, including regular calibration of batching equipment, testing of constituent materials, and documentation of all production parameters.

Choosing the Right Concrete Supplier

Selecting the right supplier is crucial for project success. Key factors to consider include:

Location and Delivery Radius: Choose a supplier with batching plants positioned to serve your project efficiently. Long transport distances can affect concrete workability and increase costs.

Technical Expertise: Look for suppliers with qualified technicians who can recommend appropriate mix designs for your specific applications and provide technical support throughout your project.

Quality Assurance: Verify that your supplier maintains comprehensive testing programs and can provide certified test results for delivered concrete.

Equipment and Fleet: Modern, well-maintained mixer trucks ensure reliable delivery and product quality. Ask about fleet size and backup capabilities to avoid project delays.

Customer Service: Responsive customer service is essential for coordinating deliveries and addressing any issues that may arise during construction.

Environmental Considerations

Ready mix concrete offers several environmental advantages over site mixing. Centralized production allows for better management of waste materials and water resources. Many modern batching plants incorporate recycling systems that process returned concrete and wash water for reuse.

The efficiency of RMC also reduces the carbon footprint of construction projects through optimized transportation, reduced material waste, and elimination of on-site mixing equipment operation.

The Future of Ready Mix Concrete in Africa

The concrete industry in South Africa continues to evolve with technological advances and changing construction needs. Digital technologies are improving order management and delivery tracking, while new admixture technologies are expanding the range of concrete properties and applications.

Sustainability initiatives are driving innovation in concrete formulations, with increased use of supplementary cementitious materials and recycled aggregates. These developments support South Africa’s construction industry goals of reducing environmental impact while maintaining high performance standards.

Conclusion

Ready mix concrete represents a fundamental shift in construction practices, offering superior quality, efficiency, and reliability compared to traditional on-site mixing. For South African construction projects of all sizes, from residential developments to major infrastructure, ready mix concrete provides the consistency and performance needed for successful outcomes.

The investment in quality ready mix concrete and reliable delivery systems pays dividends through reduced construction time, improved quality control, and enhanced project predictability. As South Africa’s construction industry continues to grow and modernize, RMC will remain an essential component of successful building practices.

Whether you’re planning a small residential project or a major commercial development, understanding the benefits and applications of ready mix concrete will help you make informed decisions that contribute to project success and long-term structural performance.

Talk To Us About Ready Mix Concrete

More Articles on Ready Mix Concrete

Troubleshooting Uneven Concrete Mix

In the ready-mix concrete business, consistency is king. When a customer rejects a load because of an uneven concrete mix—with streaks of sand, aggregate clumps, or inconsistent slump—it's a direct hit to your bottom line and your reputation. The immediate question...

The Evolution of Concrete Mixer Drums

The ready-mix concrete industry, a cornerstone of modern construction, owes its existence to a series of brilliant innovations in mobile mixing technology. The journey from the very first rudimentary mobile mixers to the high-tech, efficient systems we see today is a...

Concrete Production in Cold Weather: Protecting Your Batch Plant Components

While much of South Africa enjoys a mild climate, the high-altitude regions of the Highveld, including Gauteng and the Free State, as well as parts of the Western Cape, can experience significant frost and freezing temperatures during the winter months. For concrete...

Concrete Production Automation: Tomorrow’s Batching Plants

The concrete production industry, long seen as a traditional, heavy-duty sector, is on the cusp of a technological revolution. The same forces of automation, the Internet of Things (IoT), and data analytics that have transformed other industries are now making their...

Batching Plant Dust Control Solutions: Protecting People, Projects, and the Planet

Dust control is no longer just a regulatory requirement—it’s a fundamental aspect of modern construction and concrete production. At Nsimbi Engineering, we understand that effective batching plant dust control solutions are essential for the safety, efficiency, and...

High-Capacity Concrete Mixers: Powering Construction Projects

High-capacity concrete mixers represent the cornerstone of modern large-scale construction operations, delivering the production volumes and mixing efficiency required for major infrastructure projects, commercial developments, and industrial facilities. These...

Ready-Mix Concrete Machinery: Boosting Construction Efficiency

The global construction industry is increasingly adopting ready-mix concrete machinery (RMC) for its unparalleled efficiency, consistency, and quality. At Nsimbi Engineering, we understand that the backbone of successful RMC operations lies in state-of-the-art...

On-Site Concrete Mixing Solutions

Modern on-site concrete mixing solutions revolutionize construction project delivery by bringing production directly to job sites. These versatile systems eliminate transportation delays, reduce costs, and provide unprecedented control over concrete quality and...

Heavy Equipment for the Cement Industry

In this guide, we explore the key heavy equipment used in the cement industry, their functions, and how Nsimbi Engineering provides high-quality machinery and parts to keep your operations running seamlessly. Construction relies on heavy equipment to ensure smooth...

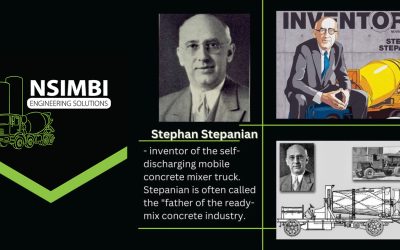

Introducing Stephen Stepanian: The Father of the Ready-Mix Concrete Industry

In the ever-evolving construction industry, innovation is key to efficiency and quality. At the forefront of this transformation in South Africa is Nsimbi, a company specializing in ready-mix concrete trucks, parts, and concrete batching plants. A significant part of...

Concrete Construction Materials: Eco-Friendly Sustainability

In today's rapidly evolving construction industry, sustainability is no longer just a buzzword – it's a guiding principle driving innovation and progress. Concrete batch plants, traditionally known for their role in producing essential concrete construction materials,...

Ready Mix Concrete Trucks

Nsimbi Engineering's ready mix concrete trucks are subject to a myriad of regulations and standards aimed at ensuring safety, environmental protection, and operational efficiency. Let's explore how these vehicles navigate regulatory compliance and uphold industry...

Mixer Truck Concrete: Maximizing Efficiency and Quality

In the construction industry, efficiency and quality are paramount. Every project demands precision and reliability to ensure lasting results, so when it comes to cement, nothing beats the efficiency and convenience of mixer truck concrete. Mixer truck concrete, also...

Ready Mix Cement Trucks: Streamlining Construction Projects

In the bustling world of construction, efficiency and reliability are non-negotiable. Every project requires seamless coordination and top-notch equipment to ensure success. That's where Nsimbi Engineering's ready mix cement trucks come into play, offering a...

Ready Mix Trucks in Construction

In the fast-paced world of construction, time is money. Every minute saved translates to increased efficiency and reduced costs. Nsimbi Engineering's ready mix trucks revolutionise the way concrete is delivered and used on construction sites. Let's explore the...