CONCRETE PRODUCTION EQUIPMENT

Concrete Trucks, Mixers And Drums

Concrete trucks, mixers, and drums are vital components in the construction industry, engineered to transport and mix concrete efficiently. Equipped with rotating drums, concrete trucks keep the concrete in motion, preventing it from hardening during transport. These mixers come in various sizes and configurations, offering flexibility on job sites. With advanced features for mixing and delivering concrete, they ensure that high-quality concrete reaches its destination in optimal condition, making them indispensable for any construction project.

Nsimbi Truck Mounted Mixer Units

Nsimbi fabricates truck mounted mixer units. We supply 6m and 8m mixer units.

The mixer drums are fabricated from a steel that provides increased life expectancy of drums.

The hydraulic package is a reliable unit and low maintenance package. All mixers are painted in 2K high glass.

Critical and wear spares are readily available from our stores.

Drum Units

We manufacture drums compatible with most mixer units currently used in the construction industry.

Drum Specifications:

- Material: Drums are constructed from S355JR steel for durability.

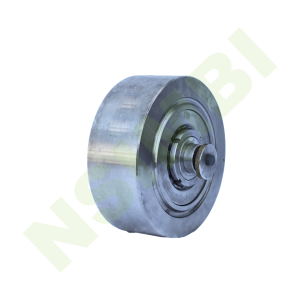

- Track Ring: Machined from a solid billet of high-wear-resistant carbon steel.

- Blades: Made from S355JR steel, with welded capping on the edges to enhance blade longevity.

- Mixing Paddle: All drums are equipped with mixing paddles to optimize mixing efficiency.

We maintain stock of drums for TFM, Liebherr, Stetter and FAW units (T’s & C’s apply).

Dry Mix Concrete Batch Plants

Dry mix concrete batch plants are essential assets in the construction industry, meticulously designed for the efficient and precise blending of raw materials. These plants mix aggregate, cement, and other components without water, offering unparalleled control over the concrete composition. The dry mix process ensures a consistent, high-quality product that can be transported to various job sites and mixed with water as needed. With various configurations and advanced features, dry mix concrete batch plants provide the flexibility and reliability necessary for any construction project, ensuring optimal performance and quality.

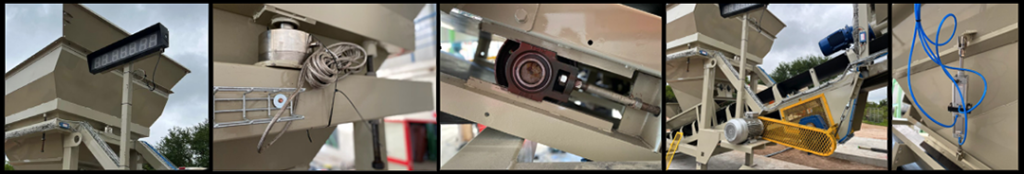

C-Type 36-42 Plant

C-Type 36-42 Plants are designed to provide efficient and reliable concrete production with a production rate of 36 to 42 cubic meters per hour. This plant is ideal for projects that require a consistent and high-quality dry mix concrete supply. Its compact design ensures easy installation and mobility, making it suitable for both temporary and permanent setups. With advanced control systems and durable components, the C-TYPE: 36 – 42 Plant delivers exceptional performance and precision, meeting the demands of modern construction projects.

Water Scale and Reticulation System

Our Water Scale and Reticulation Systems feature a robust 2000-litre capacity water scale, equipped with three 2-ton compression load cells for precise measurement and control. This system ensures accurate water dosing, essential for maintaining the quality and consistency of concrete mixes. Water is gravity-fed into the mixing truck via a specialized water ring, optimizing the delivery process. Additionally, the plant is equipped with an 800-liter per minute feed and pressure pump, providing a reliable water supply with a checkpoint to ensure consistent flow and pressure. This advanced system guarantees efficient water management, enhancing the overall performance and reliability of the concrete batching process.

Aggregate Scale and Conveyor System

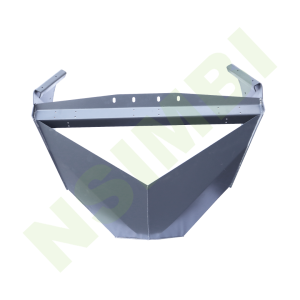

Our Aggregate Scale and Conveyor System is designed for efficiency and precision, featuring an aggregate hopper with a capacity of 6m³ to 8m³. This system utilizes three 10-ton compression load cells with an integrated scoreboard, ensuring accurate measurement and monitoring of aggregate quantities. The hopper is complemented by a robust conveyor belt system equipped with a tensioning device for optimal performance. Powered by an 11 kW drive and a separate 13:1 gearbox, the 750 mm wide conveyor belt facilitates smooth and efficient material transfer. Additionally, a twin-cylinder operation system is employed to open the gate, providing seamless access to aggregates while enhancing operational reliability.

Cement Scale System

The Cement Scale System is engineered for precision and efficiency, featuring a robust scale with a 3-ton capacity. This system includes a 273 mm diameter screw conveyor designed to accurately dose cement into the mixer truck, ensuring optimal mixing consistency. The scale is equipped with four 2-ton compression load cells, providing precise weight measurement and reliable performance. With this advanced system, operators can confidently manage cement dosing, contributing to the overall quality and reliability of concrete production.

Electrical and Pneumatic System

The Electrical and Pneumatic System is designed for both manual operation and seamless integration with advanced batching software, offering flexibility and precision in concrete production. This system features a central pneumatic control housed in a dust-proof steel enclosure, ensuring durability and protection against environmental factors. Equipped with a powerful 7.5 kW compressor, it provides reliable pneumatic power for various operations, enhancing the overall efficiency of the batching process. With this comprehensive system, operators can efficiently manage and control the batching process, ensuring consistent and high-quality concrete output.

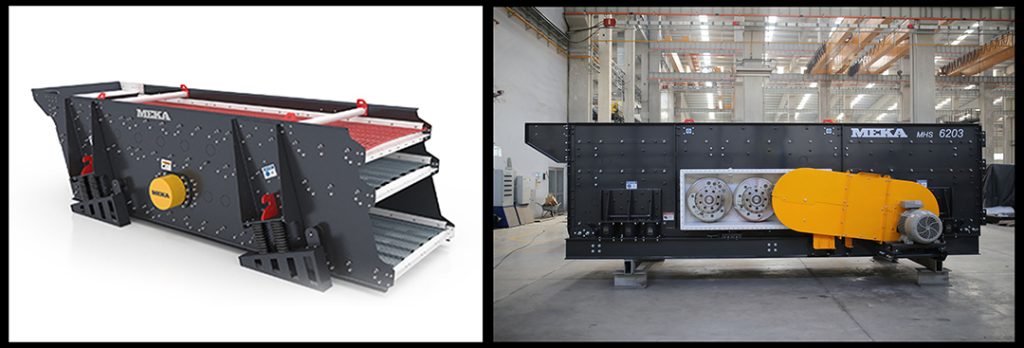

Meka Concrete Batch Plants, Crushing, Screening & Mining Equipment

Nsimbi Engineering Solutions has formed a strategic alliance with MEKA Global, a premier manufacturer of high-quality machinery for the aggregate and concrete industries. Through this partnership, Nsimbi Engineering Solutions is the exclusive representative of MEKA products in South Africa, delivering cutting-edge solutions in crushing, screening, and concrete batching technologies to the region.

Crushing Equipment

Meka Crushing equipment is essential in the construction and mining industries for breaking down large rocks, gravel, and other materials into smaller, more manageable pieces. This equipment is crucial for producing aggregate used in concrete, road construction, and various other applications. High-quality crushers come in various types, including jaw crushers, cone crushers, and impact crushers, each designed to handle different materials and achieve specific results. Investing in reliable crushing equipment ensures efficiency, durability, and optimal performance, helping projects stay on track and within budget.

Screening Equipment

Screening equipment is vital in the aggregate and concrete industries for separating materials by size. Meka’s screening equipment ensures that only the appropriately sized materials are used in the production process, enhancing the quality and consistency of the final product. Screens can handle a variety of materials, from fine sand to large gravel, and are designed to operate efficiently under tough conditions. Reliable screening equipment helps streamline operations, reduce waste, and improve productivity, making it an indispensable part of any concrete batching plant.

Mining & Batching Technology

Nsimbi brings you a wide range of MEKA feeders, crushers, screens and washing systems that can be designed as a full complete stationary or mobile solution/complex according to the location, type of rock and individual preferences.

FEATURED TRUCK MIXER PARTS

FEATURED BATCH PLANT PARTS

Product Partners

Nsimbi Engineering Solutions has entered into an agreement with MEKA Global to represent MEKA products in South Africa. We are the official representatives of MEKA Batch Plants, Crushing Equipment and Screening Equipment. We are now in a position to sell, service and install MEKA equipment. We carry stock of drums for TFM, Liebherr, Stetter, Putzmeister, and FAW units as well as service parts for batching plants, concrete trucks and drums.