Every fleet manager faces a constant dilemma: when a part on a concrete mixer truck needs replacing, do you choose the Original Equipment Manufacturer – OEM mixer parts, or do you opt for a less expensive aftermarket alternative? The decision is not always straightforward. While the lower price of aftermarket parts can be tempting, it’s crucial to weigh this against the potential risks to performance, reliability, and even safety.

This guide provides an honest comparison of OEM and aftermarket parts for your mixer fleet, helping you make smart, informed choices that balance cost and quality.

Defining the Terms: OEM vs. Aftermarket

OEM (Original Equipment Manufacturer) Parts: These are parts made by the same company that manufactured your truck (e.g., Liebherr, Stetter). They are identical to the parts that were installed on your truck at the factory.

Aftermarket Parts: These are parts made by a different company. They are designed to fit and function in your truck but are not sourced from the original manufacturer. High-quality aftermarket suppliers, like Nsimbi Engineering Solutions, often reverse-engineer OEM parts and may even improve upon the original design or materials.

The Decision Matrix: When to Choose Which

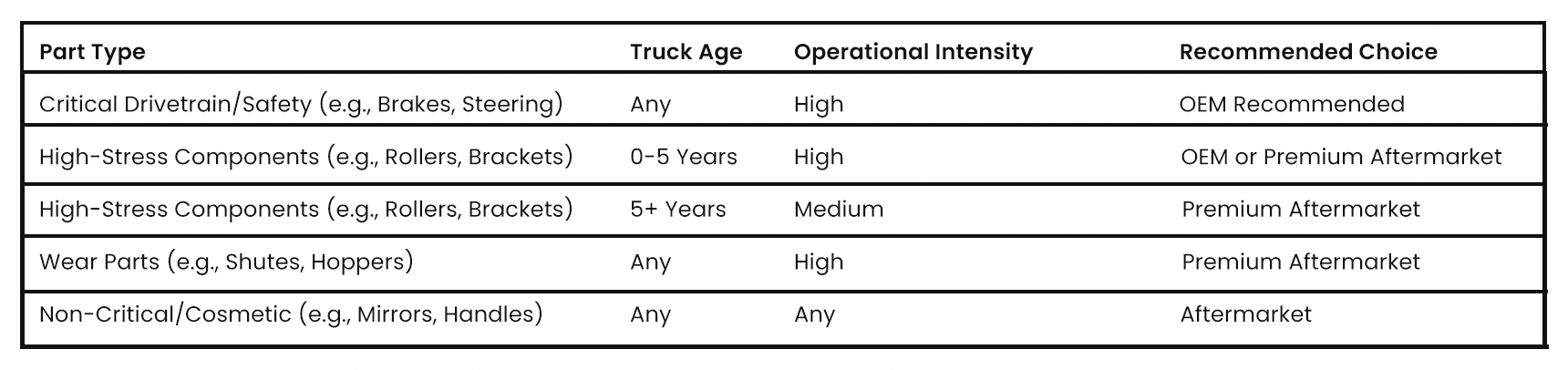

The right choice depends on the specific part, the age of the truck, and its role in your fleet. Here is a decision matrix to guide your thinking:

The Case for Premium Aftermarket Parts

It’s important to understand that “aftermarket” is not a single category. There is a vast difference between a cheap, low-quality part from an unknown source and a premium aftermarket part from a reputable supplier like Nsimbi Engineering Solutions.

Advantages of Premium Aftermarket Parts:

- Cost Savings: This is the most obvious benefit. Premium aftermarket parts can offer savings of 20-40% compared to their OEM counterparts without a significant compromise in quality.

- Quality and Innovation: Reputable aftermarket manufacturers often analyze OEM parts to identify weaknesses. They may then use a higher-grade steel, a more robust welding technique, or a better design to create a part that is actually more durable than the original.

- Availability: For older trucks, OEM parts may be difficult to find or even discontinued. The aftermarket is often the only source for these parts. Nsimbi, for example, stocks a wide range of parts for various brands, ensuring you can get what you need quickly.

When to Insist on OEM

There are certain situations where sticking with OEM is the safest bet.

- Under Warranty: If your truck is still under the manufacturer’s warranty, using non-OEM parts for a repair could void your coverage.

- Complex Electronics: For highly sensitive electronic components, an OEM part is often the only way to guarantee perfect compatibility with the truck’s software.

- Resale Value: On a newer truck, having a service history with only OEM parts can sometimes enhance its resale value, although this becomes less of a factor as the truck ages.

Making Smart Choices: Quality Indicators

When evaluating an aftermarket part, look for these signs of quality:

Supplier Reputation: Has the supplier been in business for a long time? Do they have a good reputation in the industry? Nsimbi Engineering Solutions has a proven track record of supplying quality parts to the South African construction sector.

Material Specification: Can the supplier tell you what kind of steel the part is made from? A reputable supplier will be transparent about their materials.

Weld Quality: Look for clean, consistent welds. Messy, uneven welds are a major red flag.

Warranty: Does the supplier stand behind their product with a warranty?

Conclusion

The OEM vs. aftermarket debate is not about which is universally “better,” but about making the right choice for a specific situation. For non-critical parts, the cost savings of aftermarket components are hard to ignore. For critical safety and drivetrain components, the peace of mind of OEM mixer parts is often worth the extra cost.

For the vast majority of high-wear components on a concrete mixer truck—the rollers, brackets, shutes, and hoppers that take the most abuse—premium aftermarket parts from a trusted supplier like Nsimbi Engineering Solutions offer the perfect blend of quality, reliability, and cost-effectiveness. By making smart, informed choices, you can keep your fleet running reliably while also managing your maintenance budget effectively.