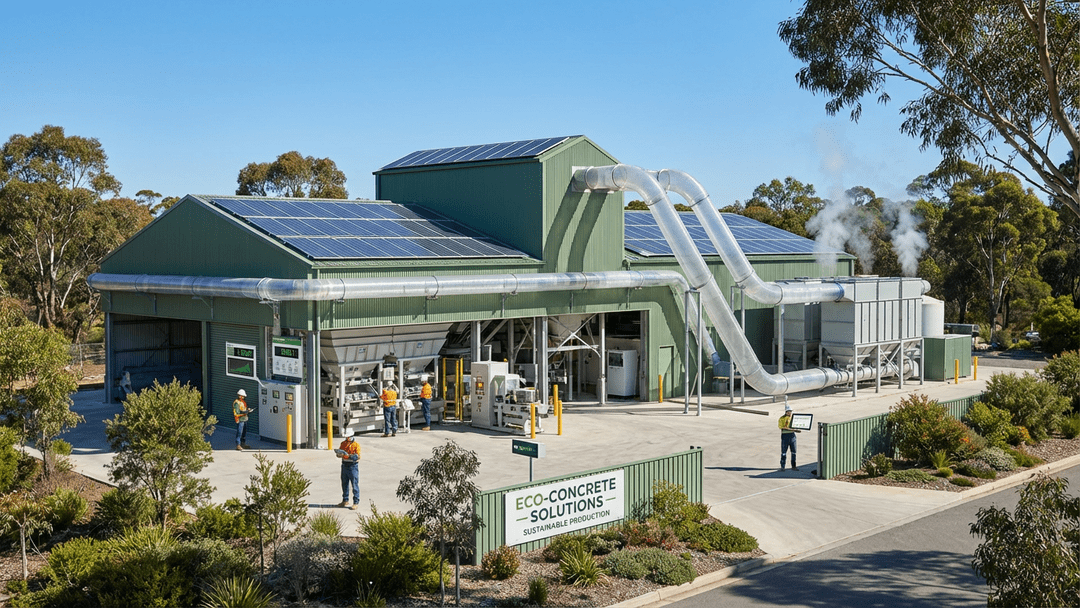

The construction industry is under increasing pressure to reduce its environmental footprint. As the most widely used construction material on the planet, concrete is a major focus of this sustainability drive. While much of the attention is on developing new, greener cement formulas, the choices made in the concrete production process itself, specifically, the equipment used in eco‑friendly batching plants, can have a significant and immediate impact on sustainability.

For South African concrete producers, investing in eco‑friendly equipment is not just about environmental stewardship; it’s also a smart business decision that can lead to cost savings, improved efficiency, and a stronger brand reputation. This article explores how strategic equipment choices, from dust collectors to efficient conveyors, can help you build a more sustainable and profitable concrete production operation.

The Pillars of Sustainable Concrete Production

Sustainable production in a batching plant revolves around three key principles:

Resource Efficiency: Using less energy, water, and raw materials for every cubic metre of concrete produced.

Pollution Prevention: Minimising the release of dust, noise, and wastewater into the environment.

Waste Reduction: Reducing the amount of wasted material and promoting recycling.

Equipment Choices for eco‑friendly batching plants: Nearly every component in a batching plant can be optimised for sustainability.

1. High‑Efficiency Dust Collectors

This is the most visible and impactful sustainability investment you can make. A modern, efficient dust collector, like those supplied by Nsimbi Engineering Solutions, does more than just clear the air.

Environmental Benefit: It prevents the release of harmful particulate matter into the atmosphere, protecting local air quality and ensuring compliance with South Africa’s Air Quality Act.

Economic Benefit: The collected dust is valuable cement that is returned directly to your silo instead of being lost to the wind. This can reduce your overall cement consumption by up to 1 %.

2. Efficient Conveyor Systems

The belts that transport your aggregate are major consumers of electricity.

Environmental Benefit: A well‑designed conveyor system with high‑efficiency motors and gearboxes, like those found in MEKA batch plants, can significantly reduce your plant’s overall energy consumption. Shorter conveyor runs in a compact plant layout further enhance this effect.

Economic Benefit: Lower energy consumption directly translates to lower electricity bills, a significant operational saving in South Africa’s high‑cost energy environment.

3. Precise Water Management Systems

Water is a precious resource in South Africa. A precise water management system is key to both sustainability and quality control.

Environmental Benefit: An automated system with an accurate water meter ensures that not a single drop of water is wasted. This reduces the overall water footprint of your operation.

Economic Benefit: Preventing the use of excess water not only saves on water costs but also ensures a consistently low water‑cement ratio, leading to higher‑strength concrete and fewer rejected loads.

Calculating the Benefits: Investing in sustainable equipment provides a tangible return.

Here’s a clean markdown table that captures the three equipment options and their associated benefits, followed by a brief note on the broader strategic advantages of sustainability.

| Equipment Choice | Sustainability Benefit | Potential Financial Benefit |

|---|---|---|

| Dust Collector | Reduced air pollution | Savings from recovered cement, avoidance of fines |

| Efficient Conveyors | Lower energy consumption | Reduced monthly electricity costs |

| Water Management | Water conservation | Lower water bills, fewer rejected loads |

Additional strategic benefit

Beyond these direct savings, a demonstrable commitment to sustainability can enhance your company’s brand image, positioning you as a preferred supplier for green building projects—an increasingly common demand in South Africa. Achieving a Green Star rating from the Green Building Council of South Africa (GBCSA) for your projects can provide a significant competitive advantage.

Conclusion

Sustainability in concrete production is not a trend; it is the future of the industry. The equipment you choose to operate in your batching plant has a direct and measurable impact on your environmental footprint and your bottom line. By investing in high‑efficiency dust collectors, optimised conveyor systems, and precise water management technology, you can create a “triple win”: a healthier environment, a more profitable business, and a stronger, more resilient brand.

As a supplier of modern, efficient MEKA batch plants and high‑quality components, Nsimbi Engineering Solutions is committed to helping South African concrete producers invest in eco‑friendly batching plants and build a more sustainable future. Contact them today to learn how their eco‑friendly equipment solutions can help you reduce your environmental impact while increasing your profitability.