Of all the ingredients in a concrete mix, water is the most critical and the most variable. The precise amount of water in a batch—the water-cement ratio—is the single most important factor determining the final strength and durability of the concrete. Too much water creates a weak, porous product, while too little results in a mix that is unworkable. Effective water management is therefore not just a part of the batching process; it is the very heart of quality control. Robust batch plant water systems are a combination of accurate measurement, precise control, and protection against system failures. This guide explores the key components of a modern batch plant water system, from meters to regulators, and discusses the impact of water quality on your final product.

The Importance of the Water-Cement Ratio

The water-cement ratio (w/c ratio) is the weight of the water in the mix divided by the weight of the cement. A lower w/c ratio generally leads to higher strength and durability. For most standard concrete applications, a w/c ratio between 0.45 and 0.55 is targeted. Achieving this precise ratio, batch after batch, requires a water delivery system that is both accurate and repeatable.

Key Components of Batch Plant Water Systems

A reliable water system consists of several key components working in concert:

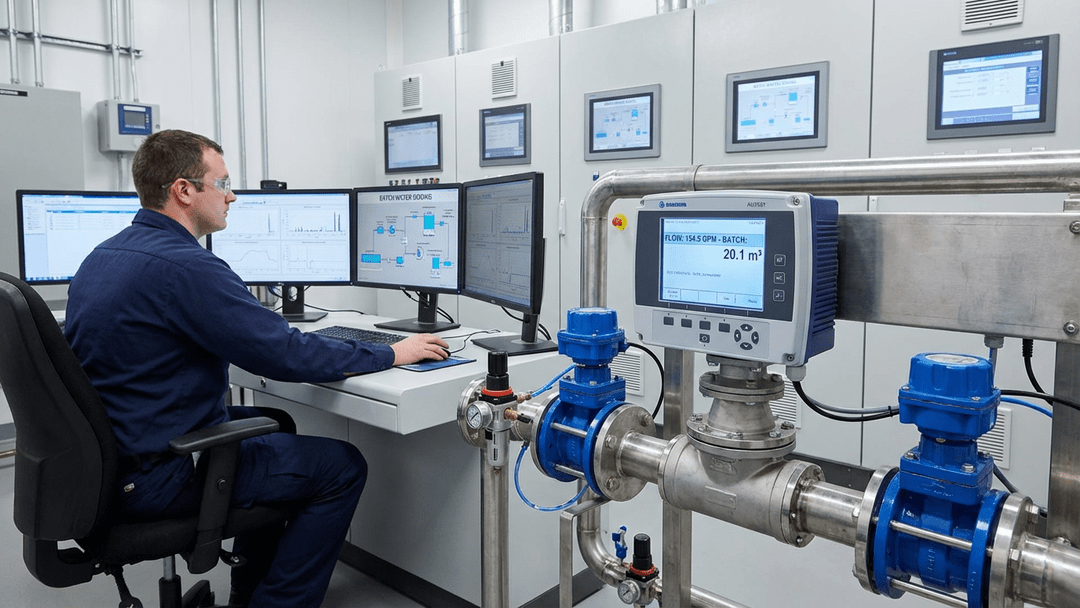

1. The Water Meter

This is the cash register of your water system. It measures the exact volume of water delivered to the mixer. Modern batch plant water systems use highly accurate electronic water meters with a pulse output that integrates directly with the plant’s automation system. The automation system is programmed with the required water amount, and it closes a valve once the meter has registered that the correct volume has passed through.

- Maintenance: Water meters should be calibrated at least once a year to ensure their accuracy. Debris in the water supply can damage the meter’s internal turbine, so installing a simple Y-strainer (filter) upstream of the meter is a wise investment.

2. The Water Pump and Piping

The pump and piping must be sized to deliver the required volume of water to the mixer in a timely manner. A pump that is too small will slow down your batching cycle, while one that is too large can create pressure surges (“water hammer”) that can damage your meter and valves.

3. The Air Regulator with Water Trap

Many batch plant control systems use pneumatic (air-powered) valves to control the flow of water. The compressed air that operates these valves must be clean and dry. An Air Regulator with Water Trap, available from Nsimbi Engineering Solutions for around R1,215, is an essential component. It performs two functions:

- Regulates Pressure: It ensures the valve receives air at the correct, stable pressure for consistent operation.

- Traps Water: It removes moisture from the compressed air, preventing it from causing corrosion or freezing in the valve’s control mechanism during cold weather.

The Impact of Water Quality

The quality of your mix water can also have a significant impact on the final concrete product. Water used for concrete should be free from contaminants like oils, acids, alkalis, and organic matter. Using “grey water” or water from untested sources is a major risk.

- Filtration: While not always necessary, if your water source has a high level of suspended solids (silt or clay), it can affect the bond between the cement paste and the aggregate. Basic filtration can improve the water quality and also protects your water meter and valves from damage.

Achieving Consistent Results

Achieving a consistent w/c ratio batch after batch requires a holistic approach:

System Aspect: Measurement

Key to Consistency: A regularly calibrated, high-accuracy water meter.

System Aspect: Control

Key to Consistency: A reliable, automated valve system with clean, dry compressed air supplied via a regulator with a water trap.

System Aspect: Material

Key to Consistency: Consistent moisture content in your sand and aggregate. A moisture sensor in the aggregate bins can allow the automation system to automatically adjust the amount of mix water added.

System Aspect: Quality

Key to Consistency: A clean, reliable water source, free from contaminants.

Conclusion

Precise and reliable water management is the cornerstone of quality concrete production. It is a system of interconnected components, where the failure of one part—be it a faulty meter, a sticking valve, or a contaminated water source—can compromise the quality of your entire output. By investing in accurate measurement devices, protecting your control systems with components like air regulators and water traps, and paying close attention to your water quality, you can ensure that every batch of concrete you produce is strong, durable, and meets the exact specifications your customers demand.

For robust water meters, air regulators, and other essential batch plant water systems components, contact Nsimbi Engineering Solutions. Their high-quality parts provide the reliability you need to take control of your concrete quality.