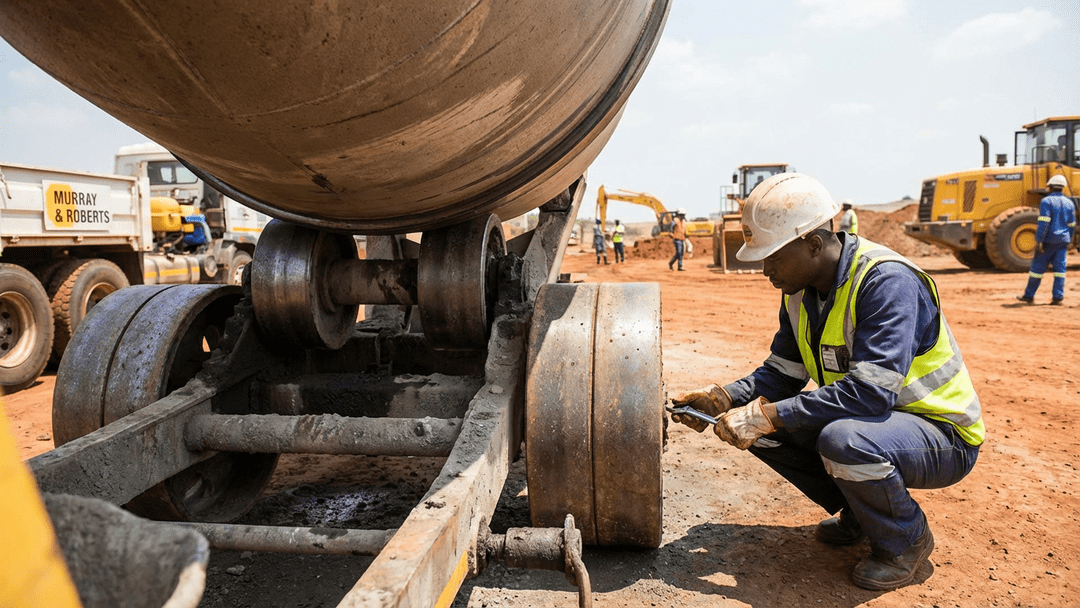

In the demanding world of construction, the reliability of your equipment is paramount. For concrete mixer trucks, the drum rotation system is the heart of the operation, and the mixer drum rollers are the critical components that keep it beating. A failure in these seemingly small parts can lead to catastrophic downtime, project delays, and significant financial losses. This article explores the function of concrete truck rollers, the importance of quality, and how investing in the right parts can save you money in the long run.

The Function of Mixer Drum Rollers

Concrete truck rollers are heavy-duty components that support the weight of the concrete-filled drum and allow it to rotate smoothly. They are constantly under immense pressure and subject to continuous wear and tear. The quality of these rollers directly impacts the performance and lifespan of your mixer truck. High-quality rollers, such as the ones offered by Nsimbi Engineering Solutions for brands like Liebherr, Stetter, TFM, FAW, ECEM, and Putzmeister, are manufactured from durable materials to withstand the harsh conditions of a construction site.

The Cost of Downtime: A Real-World Scenario

Consider a scenario where a concrete mixer truck is on its way to a critical pour. A cheap, low-quality roller fails, causing the drum to seize. The truck is now out of commission, and the concrete inside begins to harden. The direct costs include:

- Emergency Repairs: The cost of a mobile repair unit and a replacement roller.

- Lost Concrete: The entire batch of concrete is wasted.

- Project Delays: The pour is delayed, potentially impacting the entire construction schedule and incurring penalties.

Indirect costs can be even more substantial, including damage to your company’s reputation and the potential loss of future contracts. The cost of a single hour of downtime for a concrete mixer truck can run into thousands of Rands, far exceeding the initial savings from purchasing a cheaper roller.

Here’s the cost breakdown formatted as a markdown table:

| Cost Component | Estimated Cost (ZAR) |

|---|---|

| Emergency Roller Replacement | R 5,000 – R 10,000 |

| Wasted Concrete (6 m³) | R 6,000 – R 8,000 |

| Downtime (4 hours) | R 4,000 – R 8,000 |

| Total Immediate Cost | R 15,000 – R 26,000 |

Cost-Per-Operating-Hour: The Smart Way to Evaluate Rollers

Instead of focusing on the initial purchase price, a more insightful approach is to calculate the cost-per-operating-hour. A premium roller may cost more upfront, but its extended lifespan and reliability result in a lower overall cost.

- Premium Roller (e.g., NES006 Liebherr 8M – R6,698.18): Lasts for 4,000 hours. Cost-per-hour = R1.67

- Budget Roller: Costs R3,000 but lasts only 1,500 hours. Cost-per-hour = R2.00

While the premium roller has a higher initial cost, it provides a 16.5% lower cost-per-operating-hour and significantly reduces the risk of premature failure and associated downtime costs.

Signs of Wear and When to Replace

Regular inspection of your concrete truck rollers are crucial for preventing unexpected failures. Look for these signs of wear:

- Visible Wear: Flat spots, cracks, or excessive grooving on the roller surface.

- Unusual Noises: Grinding or squealing sounds during drum rotation.

- Increased Vibration: Excessive vibration can indicate a worn or failing roller.

- Difficult Rotation: If the drum struggles to rotate, the rollers may be seized or worn.

If you notice any of these signs, it’s time to replace your rollers. Nsimbi Engineering Solutions offers a wide range of high-quality replacement rollers for all major mixer truck brands, ensuring you get the right part for your equipment.

Conclusion

Mixer drum rollers are a small but critical component of your concrete mixer truck. Choosing high-quality rollers from a reputable supplier like Nsimbi Engineering Solutions is a smart investment that will pay dividends in the long run. By reducing the risk of costly downtime, extending the lifespan of your equipment, and ensuring the smooth operation of your mixer fleet, you can protect your bottom line and keep your projects on track. Don’t let a small part cause a big problem – invest in quality and reliability.