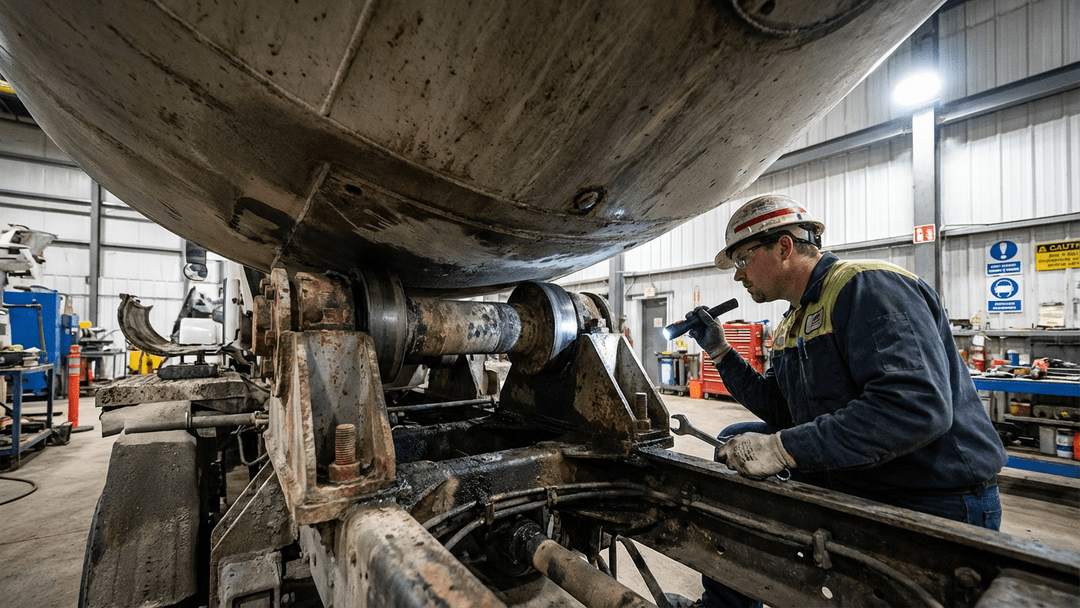

In the complex machinery of a concrete mixer truck, the massive rotating drum is the most visible component. The powerful engine and hydraulic systems get their due respect. But quietly holding it all together are the cement drum roller brackets, the unsung heroes of the drum support system. These robust steel components may not look glamorous, but their integrity is absolutely critical to the safe and efficient operation of the entire vehicle.

A failure in a roller bracket is not a minor inconvenience; it can be a catastrophic event, leading to the drum detaching, causing massive damage, and creating a serious safety hazard. This is why understanding the role of roller brackets and investing in high-quality replacements is a non-negotiable aspect of fleet maintenance.

The Critical Role of Cement Drum Roller Brackets

Roller brackets, such as the NES012 for ECEM 6M (R2,126.26) or the NES016 for Stetter 8M (R2,126.36), serve a single, vital purpose: they securely mount the mixer drum rollers to the truck’s chassis. They are the bridge that transfers the immense weight of the concrete-filled drum—often exceeding 15 tons—to the vehicle’s frame.

From an engineering perspective, these brackets are designed to withstand a complex combination of forces:

- Static Load: The immense, constant weight of the drum and its contents.

- Dynamic Load: The shifting, sloshing forces of the concrete as the truck moves and the drum rotates.

- Torsional Stress: The twisting forces generated by the hydraulic motor that turns the drum.

- Vibration: The constant, high-frequency vibrations from the engine, road, and drum rotation.

Material Fatigue and Failure Modes

Like any component subjected to repeated stress, roller brackets are susceptible to metal fatigue. Over thousands of operating hours, microscopic cracks can begin to form, typically originating at high-stress points like weld joints or bolt holes. If not detected, these cracks can propagate, leading to a sudden and complete failure of the bracket.

Common Failure Modes:

- Weld Failure: The weld connecting the bracket to the chassis is a common point of failure, especially if the original weld was of poor quality or has been compromised by rust.

- Bolt Hole Cracking: The holes where the roller is bolted to the bracket are concentration points for stress. Cracks can radiate outwards from these holes.

- Bending or Deformation: An overloaded truck or a sudden shock (like hitting a large pothole) can cause the bracket itself to bend, throwing the roller out of alignment and accelerating wear on all related components.

Why Investing in Quality Cement Drum Roller Brackets is Essential

The cost of a high-quality replacement roller bracket, such as the NES017 for TFM 6M, is minuscule compared to the potential cost of a failure. A catastrophic drum detachment can easily result in repair bills exceeding hundreds of thousands of Rands, not to mention the legal and insurance liabilities.

When sourcing replacement cement drum roller brackets, it is crucial to choose a supplier like Nsimbi Engineering Solutions that provides parts manufactured to exacting standards. Key quality indicators include:

- High-Grade Steel: The bracket must be made from steel with the correct tensile strength and fatigue resistance.

- Precision Welding: Welds should be clean, consistent, and fully penetrate the joint for maximum strength.

- Accurate Dimensions: The bolt holes and mounting surfaces must be precisely machined to ensure perfect alignment with both the roller and the chassis.

Inspection and Maintenance

Regular inspection of roller brackets should be a mandatory part of your daily vehicle check. Operators and mechanics should look for:

- Visible Cracks: Especially around welds and bolt holes.

- Signs of Rust: Rust can compromise the structural integrity of the steel and hide underlying cracks.

- Deformation: Any bending or twisting of the bracket is a red flag for immediate replacement.

- Loose Bolts: Ensure all mounting bolts are torqued to the manufacturer’s specifications.

Conclusion

Cement drum roller brackets may operate out of sight, but they should never be out of mind. They are a fundamental safety and performance component of any concrete mixer truck. By appreciating their critical engineering role, understanding the risks of failure, and committing to regular inspections and the use of high-quality replacement parts, you can prevent catastrophic failures, ensure the safety of your operators, and protect the longevity of your valuable fleet.

Don’t compromise on the components that hold your business together. Trust Nsimbi Engineering Solutions for a full range of robust and reliable roller brackets for all major mixer truck brands, including Liebherr, TFM, and ECEM.