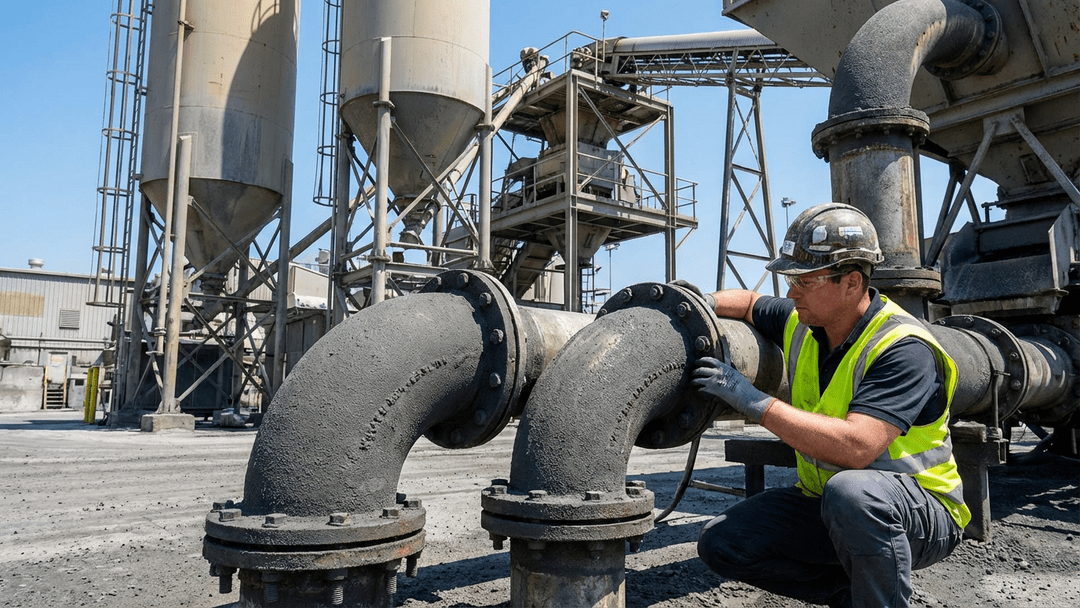

In a concrete batching plant, the pneumatic conveying system is the circulatory system that moves fine materials like cement and fly ash from storage silos to the weigh hopper. This process relies on high-velocity air to transport abrasive particles through a network of pipes. At every turn in this network, the system faces its greatest enemy: friction. Standard pipe elbows, typically used in plumbing or less demanding applications, are no match for this relentless assault and can fail in a matter of months, leading to system leaks, material loss, and costly downtime. This is where anti-wear pipe elbows prove their worth. These specialized components are engineered specifically to withstand the extreme abrasion of pneumatic conveying, dramatically extending the life of your piping system and providing a significant return on investment.

Why Standard Elbows Fail

A standard cast iron or steel pipe elbow presents a direct, 90-degree surface to the flow of abrasive material. As millions of high-velocity particles impact this surface, they act like a sandblaster, rapidly eroding the pipe wall. This phenomenon is known as “impingement wear.”

Microscopic Wear Analysis: If you were to look at the inside of a standard elbow after just a few weeks of service in a cement line, you would see a surface pitted and scored by particle impacts. Over time, this erosion thins the pipe wall until a hole is worn straight through, causing a blowout. This not only stops production but also creates a significant dust hazard.

The Science Behind Anti-Wear Elbows

Anti-wear pipe elbows are designed to mitigate impingement wear through advanced material science and clever engineering. There are two primary designs:

- Thick-Wall or Hardened Elbows: These elbows are made from a much thicker casting of a highly abrasion-resistant alloy, such as Ni-Hard or chrome white iron. The material itself is significantly harder than standard steel, and the extra thickness provides a much longer wear life. Nsimbi Engineering Solutions provides robust, thick-walled elbows designed for longevity.

- Deflection or “Vortex” Elbows: This innovative design features a spherical chamber or “vortex pocket” at the bend. As material enters the elbow, a portion of it becomes temporarily trapped in this pocket, forming a slowly rotating ball of material. The incoming stream of particles then impacts this cushioned ball of material instead of the elbow wall itself. This material-on-material impact is far less abrasive than material-on-steel, drastically reducing wear on the elbow.

Lifespan Comparison

| Elbow Type | Typical Lifespan in Cement Applications |

|---|---|

| Standard Steel Elbow | 2 – 4 months |

| Thick‑Wall Anti‑Wear Elbow | 1 – 2 years |

| Deflection/Vortex Elbow | 3 – 5+ years |

Calculating the Return on Investment (ROI)

While an anti-wear elbow has a higher initial purchase price than a standard elbow, the ROI is quickly realized through reduced downtime and replacement costs.

Scenario: A plant replacing a standard elbow 4 times per year.

- Cost of standard elbow: R 500

- Labor for replacement (2 hours): R 800

- Downtime cost (2 hours): R 2,000

- Total cost per replacement: R 3,300

- Annual Cost: R 13,200

Scenario: Installing an anti-wear elbow with a 3-year lifespan.

- Cost of anti-wear elbow: R 4,000

- Labor for installation: R 800

- Total cost over 3 years: R 4,800

- Annualized Cost: R 1,600

In this scenario, the investment in an anti-wear elbow provides an annual saving of R 11,600 for a single elbow, delivering an ROI of over 700% in the first year alone.

Installation Best Practices

To maximize the life of your anti-wear elbows, proper installation is key. Ensure that the pipes are correctly aligned to avoid creating a “step” at the joint, which can cause turbulence and accelerate wear. Use high-quality gaskets and ensure all connections are airtight to maintain system pressure and efficiency.

Conclusion

In the high-stakes environment of a concrete batching plant, every component must be optimized for reliability and longevity. Standard pipe elbows are a weak link in any pneumatic conveying system, destined for rapid failure. Anti-wear pipe elbows, available from suppliers like Nsimbi Engineering Solutions, are a technically superior and financially astute solution.

By investing in engineered, abrasion-resistant components, you are not just buying a part; you are buying uptime, reliability, and a lower total cost of ownership. Stop the cycle of frequent replacements and costly blowouts. Upgrade your pneumatic system with anti-wear elbows and let your plant run as it should—smoothly and profitably.