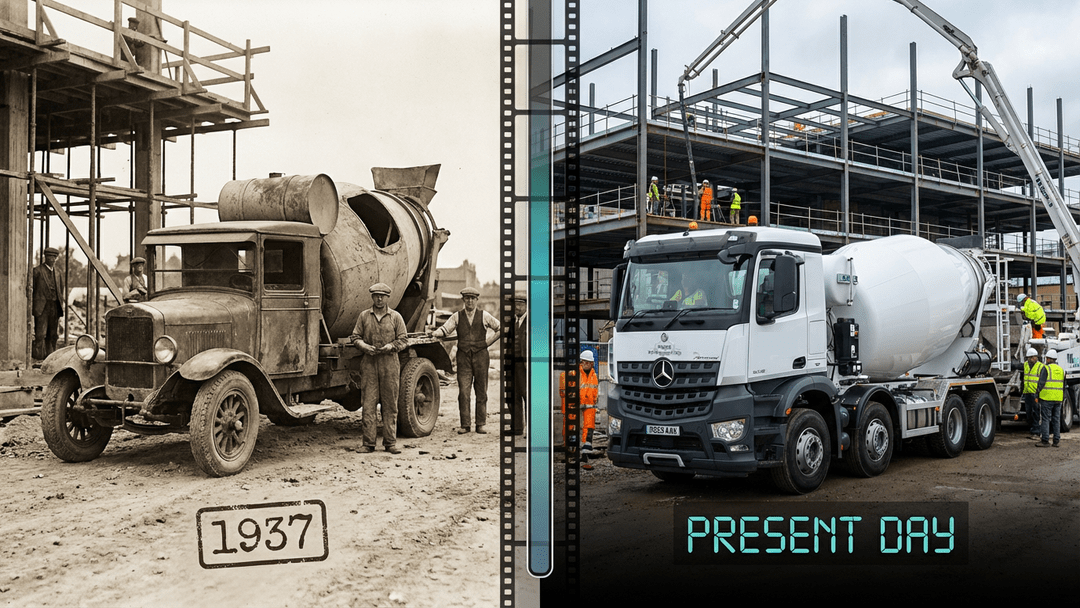

The ready-mix concrete industry, a cornerstone of modern construction, owes its existence to a series of brilliant innovations in mobile mixing technology. The journey from the very first rudimentary mobile mixers to the high-tech, efficient systems we see today is a fascinating story of engineering progress. While Nsimbi Engineering Solutions has previously honored the “Father of the Ready-Mix Concrete Industry,” Stephen Stepanian, and his early inventions, it’s worth exploring the evolution of concrete mixer drums, from its conceptual origins in the 1930s to the advanced systems offered today.

The Early Days: A Revolution on Wheels

Before the 1930s, concrete was mixed on-site, a labor-intensive and often inconsistent process. The concept of a “truck mixer” that could mix concrete while in transit was revolutionary. The vintage 1937 concrete truck mixer, a historical touchstone for the industry, represented a monumental leap forward. These early concrete mixer drums were simple in design, often little more than a rotating cylinder with a few internal paddles. Their primary goal was to agitate the material enough to prevent it from setting before it reached the job site.

Key Features of Early Drums:

- Simple Agitation: Basic internal paddles or fins.

- Mechanical Drive: Often powered by a separate, small engine.

- Limited Capacity: Typically carried much smaller loads than modern trucks.

While groundbreaking, these early designs had limitations. The mixing action was not always thorough, leading to inconsistencies in the final product. The drive systems were prone to failure, and the drums themselves were made from heavy, simple steels.

The Mid-Century: Rise of the Helical Blade

The post-war construction boom demanded more and better concrete. The most significant innovation during this period was the development of the continuous helical (or spiral) blade inside the drum. This was a game-changer.

- Mixing Action: When the drum rotates in one direction, the helical blades lift and tumble the material, creating a highly effective and consistent mixing action.

- Discharge Action: When the drum’s rotation is reversed, the same helical blades act as an Archimedes’ screw, pushing the mixed concrete out of the drum in a controlled flow.

This dual-action design, which is still the fundamental principle of modern mixers, dramatically improved the quality and consistency of ready-mix concrete. Drum capacities also began to increase, and hydraulic drive systems started to replace the less reliable mechanical ones.

The Modern Era of Concrete Mixer Drums: Efficiency and Durability

Today, mixer drum technology has reached a new level of sophistication, driven by the demands for greater efficiency, longer service life, and higher-quality concrete. Modern concrete mixer drums, including those on trucks serviced by Nsimbi and the advanced systems from partners like MEKA, are a world away from their 1930s ancestors.

1937 – 2025 Drum Modern Integrated System

- Blade Design: Simple paddles. Complex, variable-pitch helical blades for optimized mixing.

- Steel Quality: Standard mild steel. High-strength, abrasion-resistant steels for longer wear life.

- Drive System: Separate mechanical engine. Integrated, high-torque hydraulic system with variable speed control.

- Capacity: 2-3 cubic meters. 6-12+ cubic meters

- Control: Manual levers. Electronic, in-cab controls for precise drum speed and direction.

Innovations in Modern Concrete Mixer Drums:

- Variable-Pitch Blades: The angle of the helical blades may change along the length of the drum to create a more complex and thorough mixing action.

- Advanced Materials: The use of hardened, abrasion-resistant steel alloys means that modern drums can withstand the constant wear of aggregate for much longer, reducing the frequency of costly blade and liner replacements.

- Optimized Shape: The geometric shape of the drum itself is computer-modeled to promote the best possible mixing flow, eliminating “dead spots” where material can stagnate.

An Infographic of Innovation

Timeline of Mixer Drum Technology:

- 1930s: Invention of the first mobile agitator trucks.

- 1940s-50s: Development and widespread adoption of the helical blade design.

- 1960s-70s: Introduction of reliable hydraulic drive systems and increasing drum capacities.

- 1980s-90s: Use of higher-strength steels and improvements in blade design.

- 2000s-Present: Computer-aided design (CAD), variable-pitch blades, advanced alloys, and integration with electronic controls.

Conclusion

The evolution of the concrete mixer drum is a perfect example of continuous engineering improvement. From a simple rotating can to a highly engineered mixing vessel, every step in its development has been aimed at producing better, more consistent concrete, more efficiently. Today, Nsimbi Engineering Solutions is at the forefront of this evolution, providing South African contractors with access to the latest in mixing technology.

Understanding this history gives us an appreciation for the sophisticated machinery we use today. It reminds us that even a component as seemingly basic as a mixer drum is the result of decades of innovation, all aimed at building a stronger, more durable world. ”