Are you encountering issues with your Dry Mix Concrete Batching Plants? Delve into this comprehensive guide to troubleshoot common problems and optimize the maintenance of your equipment. For expert assistance, contact Nsimbi Engineering Solutions, your trusted partner in the Ready Mix Concrete Industry.

- Dry Mix Concrete Batching Plant

- Dry Mix Concrete Batching Plant with 2 Concrete Mixer Trucks

- Dry Mix Concrete Batch Plant

- Concrete Batching Plant

- Companents of a concrete batching plant

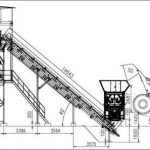

- Dry Mix Concrete Batching Plant Diagram

Troubleshooting Common Dry Mix Concrete Batching Plant Problems

Dry Mix Concrete Batching Plants play a crucial role in construction projects, but like any machinery, they may face operational issues. Identifying and addressing these problems promptly is essential to ensure uninterrupted productivity. One prevalent issue is material flow interruptions, which can occur due to blockages in the conveyor system or malfunctioning sensors. Regular inspection and cleaning of the conveyor system can prevent such interruptions. Additionally, inaccurate weighing of materials can lead to inconsistent concrete quality. Calibrating the batching equipment and regularly checking the accuracy of the weighing systems can resolve this issue. At Nsimbi we carry the essential test weights to do calibration checks and spare parts to keep your weighing equipment functioning during your production hours

Maintenance and Cleaning for Dry Mix Concrete Batching Plants

Proper maintenance is vital for the optimal performance and longevity of Dry Mix Concrete Batching Plants. Regular lubrication of moving parts, such as conveyor belts bearings and mixer components, prevents friction-related wear and ensures smooth operation. Inspecting and replacing worn-out components, such as conveyor belts and mixing blades liner plates, reduces the risk of breakdowns and improves efficiency. Moreover, thorough cleaning of the plant’s components, including the discharge shute and water ring the mixer , aggregate bins, and cement silos, prevents material buildup and contamination, ensuring consistent concrete quality.

Choosing the Right Dry Mix Concrete Batching Plant

Selecting the appropriate Dry Mix Concrete Batching Plant is crucial for achieving desired project outcomes. Consider factors such as production capacity, site constraints, and project specifications when choosing a plant model. It is crucial to identify the number of truck mixer units that you require for the day to day production. Stationary batching plants are suitable for large-scale projects with consistent production requirements, offering high production capacity and advanced features. On the other hand, mobile batching plants are ideal for projects with varying production needs or remote locations, providing flexibility and mobility. Analyze your project requirements carefully to determine the most suitable batching plant configuration for your needs.

Different Types of Batching Plants

Several types of batching plants are available, each offering distinct features and advantages. Stationary batching plants are fixed installations that offer high production capacity and precise batching accuracy. Mobile batching plants, also known as portable or compact plants, are designed for easy transportation and rapid deployment at various project sites. Additionally, modular batching plants consist of pre-assembled modules that can be easily transported and assembled on-site, offering flexibility and scalability. Each type of batching plant caters to specific project requirements, ensuring efficient and reliable concrete production. At Nsimbi we manufacture various designs of dry mix batch plant to suit customer needs . Our design is based on the traditional Karoo dry mix batch plants

Conclusion

Efficient operation and maintenance of Dry Mix Concrete Batching Plants are essential for achieving optimal project outcomes. By troubleshooting common problems and implementing proactive maintenance practices, you can enhance plant performance, minimize downtime, and ensure consistent concrete quality. For expert guidance and support in managing your Dry Mix Concrete Batching Plant, rely on Nsimbi Engineering Solutions, your trusted partner in the Ready Mix Concrete Industry.